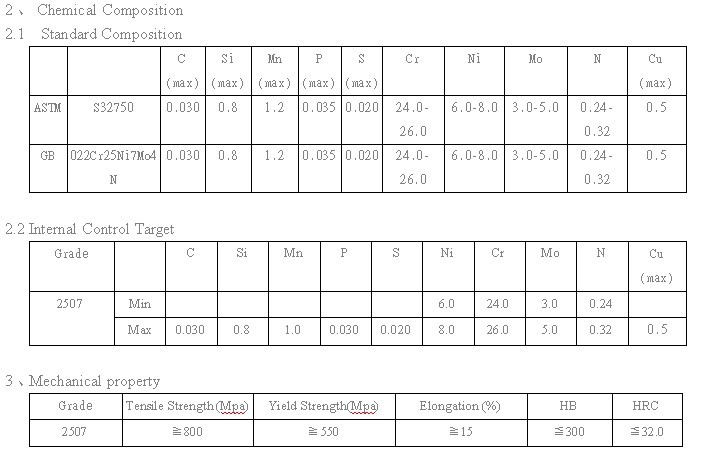

2507(UNS S32750 )

Applications:

Features:

1﹑Material Summary and Applications

2507 is a ferritic-austenitic duplex stainless steel which combines many ferritic steels and austenitic steels most useful performance.

Due to the high content of chromium and molybdenum, it has excellent resistance to pitting corrosion, crevice corrosion and uniform corrosion.

Dual-phase microstructure ensures it has high resistance to stress corrosion cracking and high mechanical strength.

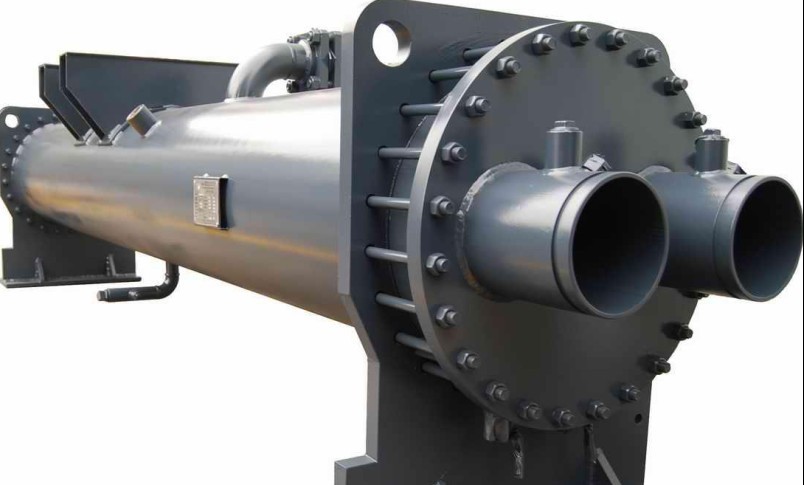

2507 stainless steel used in oil and gas industry, see platforms, heat exchanger tube, water treatment and water supply systems, fire systems, sprinkler systems, petrochemical equipment, desalination equipment.

1.3 ASTM/ASME:A240 - UNS S32750

4﹑Corrosion Resistance

High content of chromium and molybdenum make it has a strong resistance to general corrosion of organic acids, such as formic acid, acetic acid, etc..

Compare with 904L, 2507 has a better strong corrosion resistance to diluted sulfuric acid mixed with chlorine ions 904L is the austenite condition alloy, used in anti-vitriol oil corrosion specially.

316L can not be used in hydrochloric acid, it may have been localized corrosion or general corrosion.2507 can be used in diluted hydrochloric acid, it has a strong anti-spot to damage and the anti-crevice corrosion ability.

The 2507 lower carbon content greatly reduce the risk of heat treatment intergranular carbide precipitation, therefore, this alloy has a strong resistance to the carbide-related intergranular corrosion.

2507 duplex structures with strong ability to resist stress corrosion cracking. Due to its high content of alloy ,corrosion resistance and strength are superior to 2205.

5、Available Size Range for seamless pipes and tubes

OD 6 ~ 168mm

WT 1.0~12.7 mm

Copyright © 2021 Shanghai Maxmount Special Steel Co., Ltd. 沪ICP备16055057号-1 Power By : www.300.cn